Defying Gravity in a Homebuilt Airplane

Posted on October 4, 2014 by bob in Features

by Jake Roberts; photos by Bob Corley (other as noted)

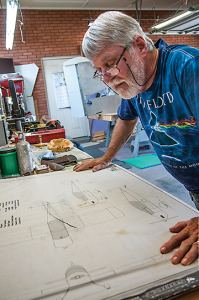

What started with Lincoln Logs and an Erector Set led Stan Tew to build an airplane.

“I always liked working with my hands,” he said, “and tinkering with stuff.”

The airplane Tew built wasn’t wire-guided from the ground or flown by remote control, but capable of carrying two people aloft and, more importantly, getting them safely back on the ground.

“I grew up playing with those types of construction sets,” he said recently while working in his garage on airplane No. #2, concluding that building a real airplane is a lot like working with those early toys.

“It’s basically an extension of an erector set,” he said, surrounded by shiny aluminum sheets and girders stacked against the wall like, well, like pieces of an Erector Set.

His first man-carrying flying machine was an ultralight, purchased in the 1980s. These are typically constructed of metal tubing and fabric and powered by a small engine, with speeds of 30 to 50 mph.

“I hung around with other ultralight pilots,” he said. “Eventually, one of them started building an airplane. I went over to his house, saw what he was doing, and thought, ‘I can do that.’ ”

And he did.

Tew, a private pilot for 18 years, is a member of Chapter 822 of the Experimental Aircraft Association (EAA), a classification under which homebuilt aircraft fall. The chapter’s home base is the Wetumpka airport.

“Why do people make puzzles?” he says when asked why he builds airplanes. “Why do they garden? Because there’s a goal at the end. When you see the flowers on the table you say ‘yes, that’s why I was outside digging in the cold ground in February.’”

But building and flying your own airplane is markedly different from assembling puzzles or growing flowers. Tew, like all pilots, recognizes this, and while it increases the consequences of shoddy workmanship, it also adds to the sense of accomplishment when the project is complete and flying safely. A friend of his has a picture of an airplane in a tree. The caption reads – “Be careful of your work; the consequences are grave.”

“Aviation,” said Tew, “is not inherently dangerous, but it’s highly intolerant of mistakes.”

Tew’s first homebuilt aircraft won top honors in his Division at the Southeast Regional Fly-in in Evergreen, AL. His longest trip in that aircraft was to AirVenture, an annual, international EAA-sponsored fly-in in Oshkosh, Wisconsin, an 800-mile journey, Tew recalled, at 60 to 80 mph.

His current project is a single-seat aluminum aircraft capable of speeds of 135 mph, but he’ll likely continue to enjoy the low-and-slow characteristics of his current plane.

“I can fly around on a Sunday afternoon,” he says, “cruising at 60-70 miles per hour, one door open, waving at people.” He smiles. “I can even smell hamburgers cooking.”